Design of 4D Printed, Deployable and Active Systems

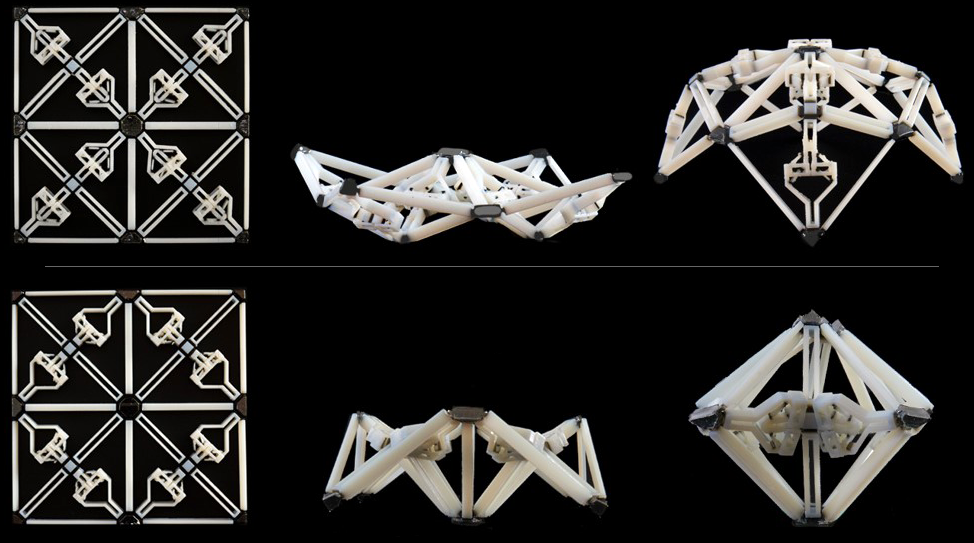

Through new multi-material AM processes we are able to locally tune the material composition of structures and "program" the material to create parts that actively change their shape and reconfigure themselves after printing in response to the environment. This is the next generation of 3D printing and has been termed “4D printing”, i.e. to include the time domain. For example, the hierarchically designed structures in the image transform between different, stable geometrical configurations using a multi-material, bi-stable joint while bearing predictable loads. The advantages are monolithic printing of mult-material joints, reduction in material and print time as well as transport space and cost. We are exploring the design of 4D printed structures and computational design tools for them. Applications include deployable and active structures for architecture, soft robotics, space and automotive.