Designing the Key of the Future

AM offers great capabilities to design complex parts and products that are performance optimized and customized. However, for designers this is highly challenging due to the vast design space of new possible geometries that can be realized using AM. So there is a close link between the design tools that take advantage of the 3D printing processes, and the processes themselves including material understanding.

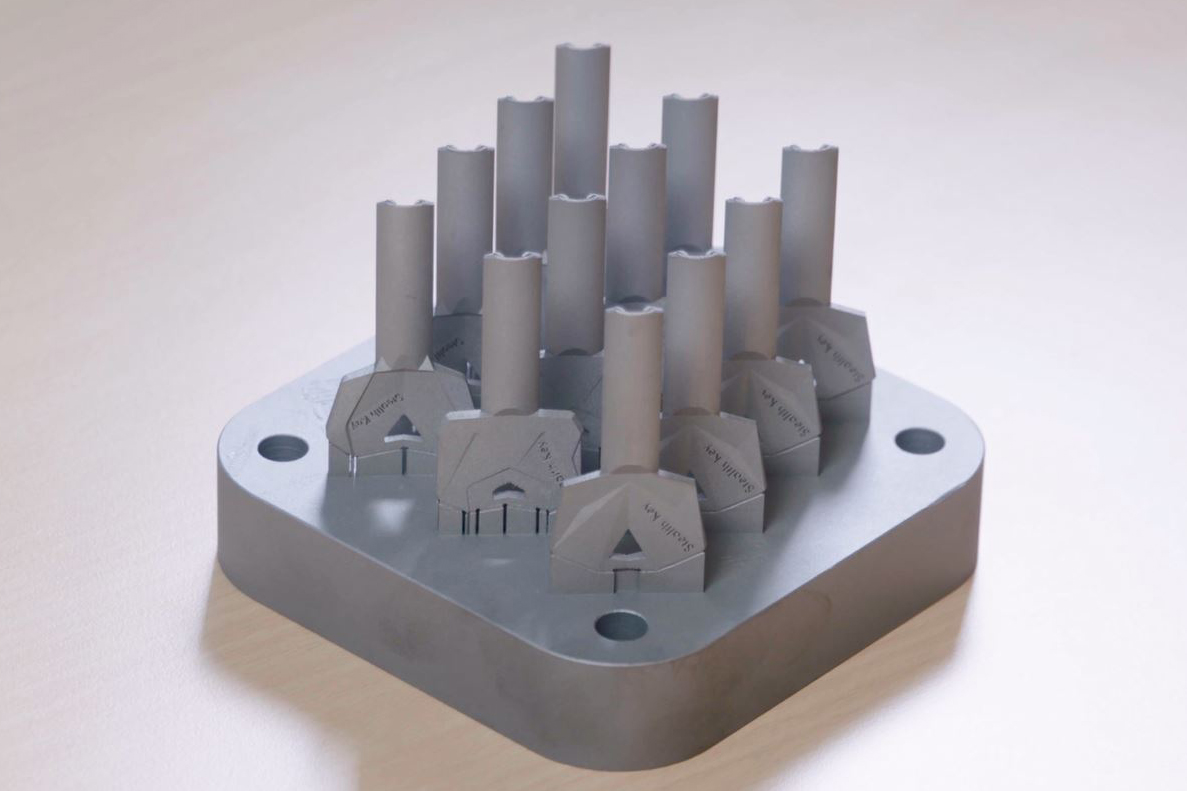

Our contribution is the development of a computational design-to-fabrication approach, methods and tools, to support the serial production of additively manufactured (AM), customized mechanical keys. This entails automated generation of complex, 3D CAD geometries that uniquely embody a key design, subject to the constraints of a particular Selective Laser Melting (SLM) manufacturing process in order to eliminate any pre- and post-processing. Additive manufacturing is just starting to be used for mass production. In this context, design automation of a customized product is being integrated together with AM fabrication pre-processing within a CAD environment. Such functionality, completely automated, is still scarce and greatly needed both in research and commercial systems. This project is a large step forward in the direction of a fully integrated, automated computational design-to-fabrication support system for AM.

The project is sponsored by Innosuisse and realized as a collaboration between ETHZ, UrbanAlps, and Bern University of Applied Sciences. The interview is produced by ETHZ Industry Relations and can also be accessed here.