Computational Design of Thermally Activated 4D Printed Structures

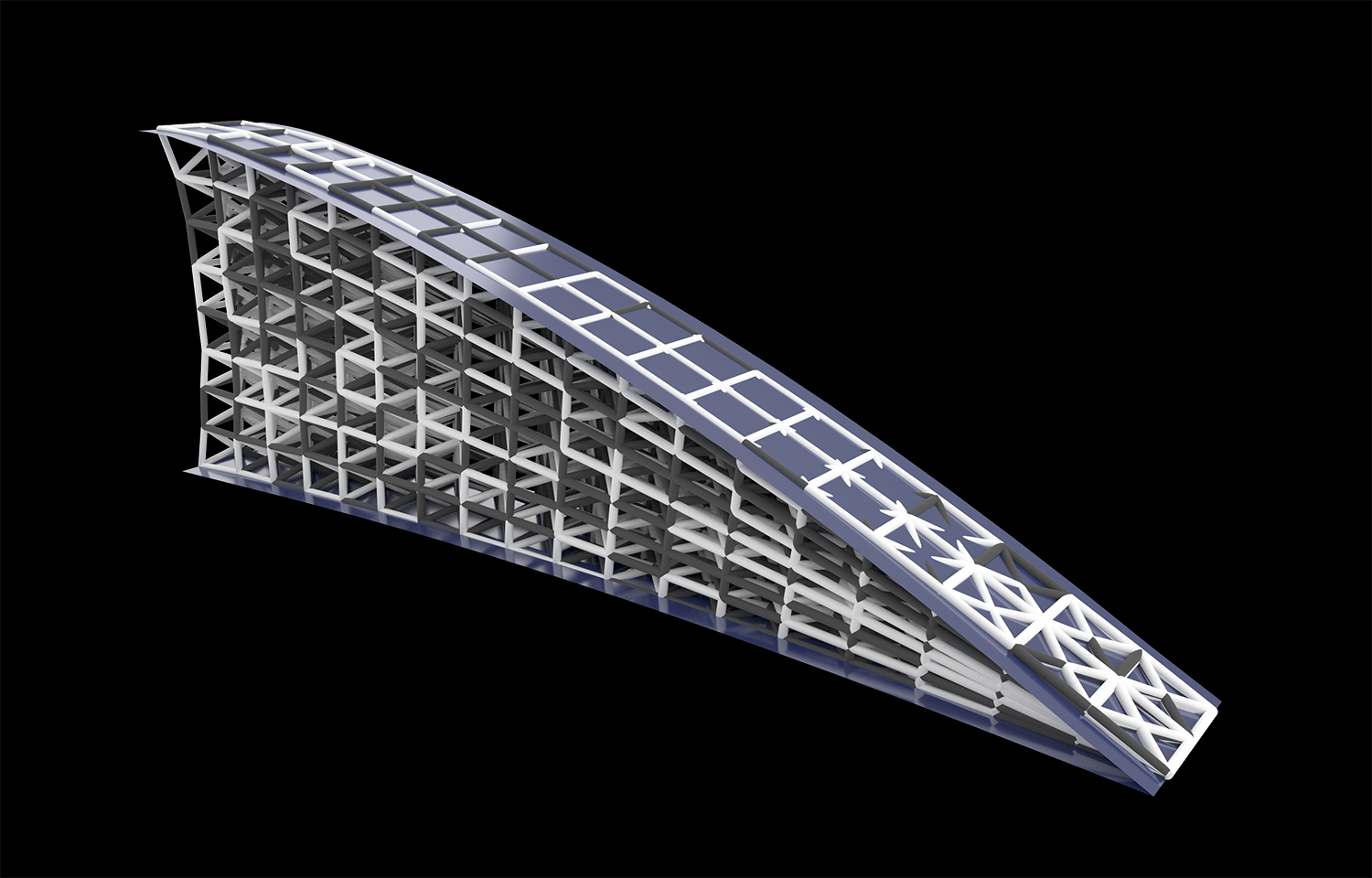

Active structures have the ability to change their shape, properties, and functionality as a response to changing operational conditions, which makes them more versatile than their static counterparts. Despite recent advances in engineering, materials science, and fabrication processes, the systematic design and fabrication of active structures is still a challenge as many structures are designed by hand in a trial-and-error process and thus limited by engineers’ knowledge and experience. This research aims to systematically design, fabricate, and test novel and active structures that can change their shape and mechanical properties in response to changes in temperature. The structures overcome known limitations such as the reversibility of deformations triggered by one-way active materials and transforming into multiple states and shapes. This is achieved by combining mechanical principles, material knowledge, multi-material 3D printing, and computational design methods. While some of the proposed concepts are limited by current 3D printing processes, the generality of both the underlying principles and the computational methods makes them directly applicable to future advances in materials science and fabrication technologies. As such, this research provides a first step towards the integrated design and fabrication of active structures and the development towards industrial applications across many length scales and fields such as the shape-morphing wings of aircraft, car panels, and building facades.